GRANITE SURFACE PLATES

Granite Surface Plates are used for precision gauging, inspection, layout and marking purposes. They are preferred by Precision Tool Rooms, Engineering Industries and Research Laboratories because of their following outstanding advantages:

No rust, no corrosion, relatively warp-free, no compensation hump when nicked, longer wear, smoother action, greater precision, nonmagnetic, less care after commissioning, lower co-efficient of thermal expansion and non-glaring surface.

SALIENT FEATURES

- Made from close grained Granite having uniform colour & texture having hardness between 5.6 to 7 on Moh's scale, sound and free from flaws fissures and large inclusions of softer minerals.

- Made generally as per IS-7327-2003. Also available on request conforming to DIN-876-1972, BS-817-1988, JIS-B-7513 and US Federal specification GGG-P-463-C.

- Rexine cover provided for top working surface with each Surface Plate.

- MS Fabricated Stand / Cupboard type / Cast Iron individual Column type Stand/Granite special Stand with Vibration Isolation Plates with leveling screws are available on request at extra cost.

- 'Metalic threaded inserts, Metalic T-slots, Plates with two or four ledges also can be supplied against specific request at extra cost..

|

|

||||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

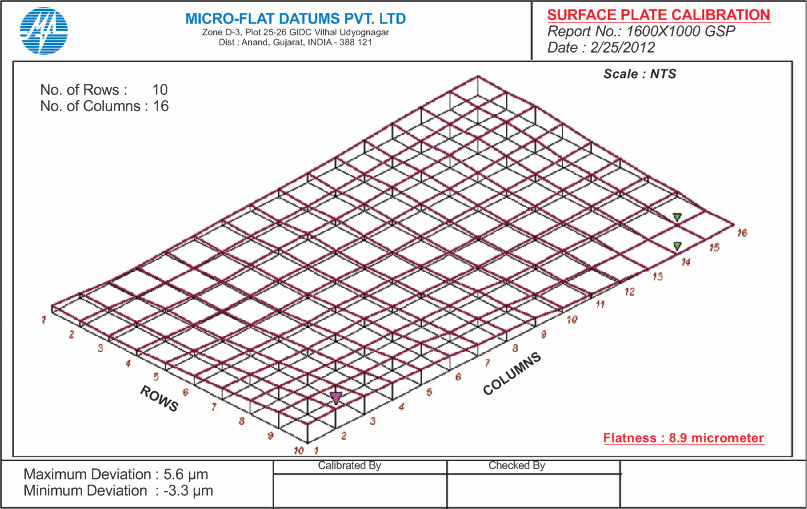

Surface Plates are provided with NABL calibration certificate traceable to National standards from our in-house calibration Laboratory including a contour plot of flatness deviation as shown below.

|

NON-STANDARD AND LARGES SIZES

|

||

|

500 X 500

|

600 X 450

|

600 X 600

|

|

750 x 500

|

750 X 600

|

800 X 600

|

|

900 X 600

|

1000 X 500

|

1000 X 600

|

|

1000 x 750

|

1200 x 800

|

1200 x 900

|

|

1200 x 1200

|

1500 x 750

|

1500 x 1000

|

|

1500 x 1200

|

1500 x 1500

|

1800 x 1200

|

|

2000 x 1250

|

2000 x 1500

|

2000 x 2000

|

|

2400 x 1200

|

2500 x 1000

|

2500 x 1500

|

|

2500 x 1600

|

2500 x 2000

|

3000 x 1000

|

|

3000 x 1250

|

3000 x 1500

|

3000 x 2000

|

|

3000 x 2500

|

3000 x 3000

|

4000 x 1000

|

|

4000 x 1500

|

4000 x 2000

|

4000 x 2500

|

|

4000 x 3000

|

5000 x 1000

|

5000 x 2000

|

|

6000 x 1000

|

6000 x 1500

|

6000 x 2000

|